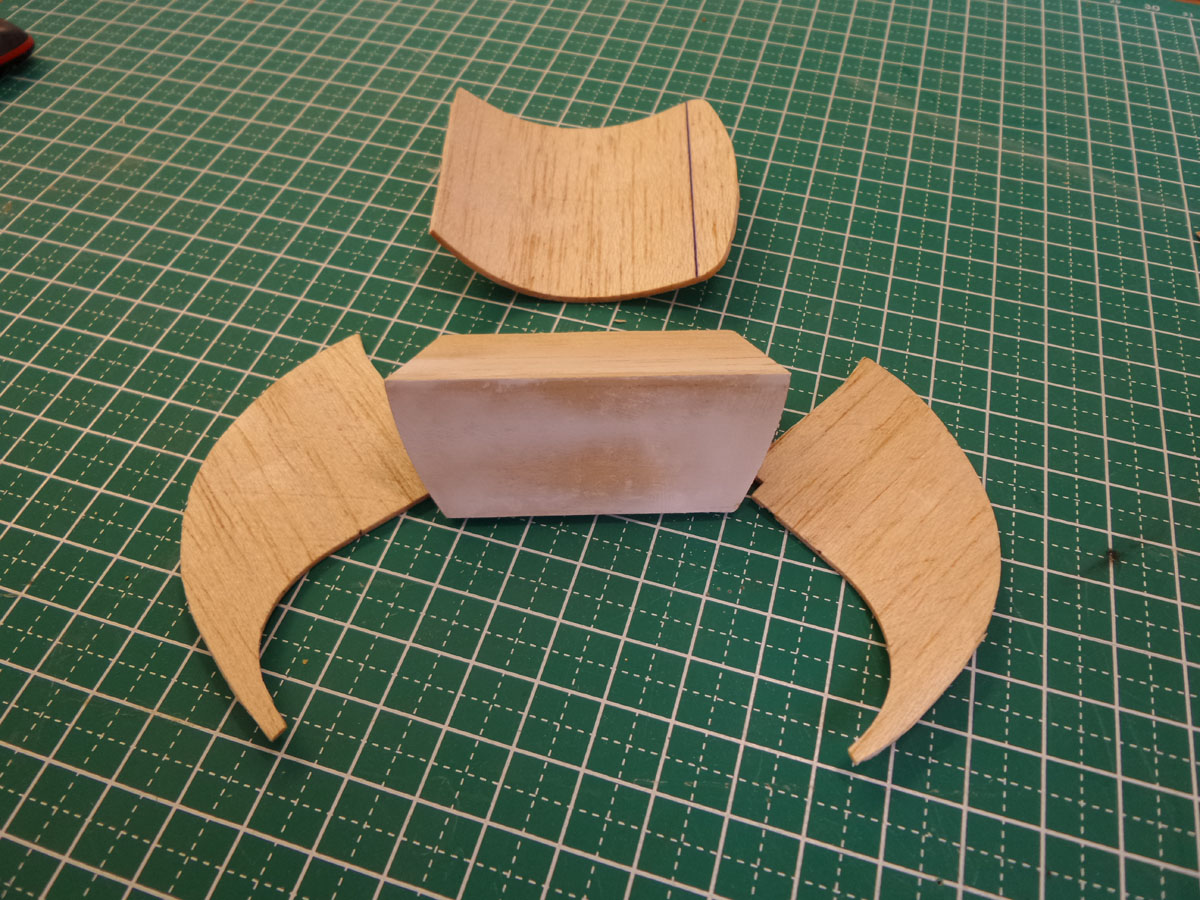

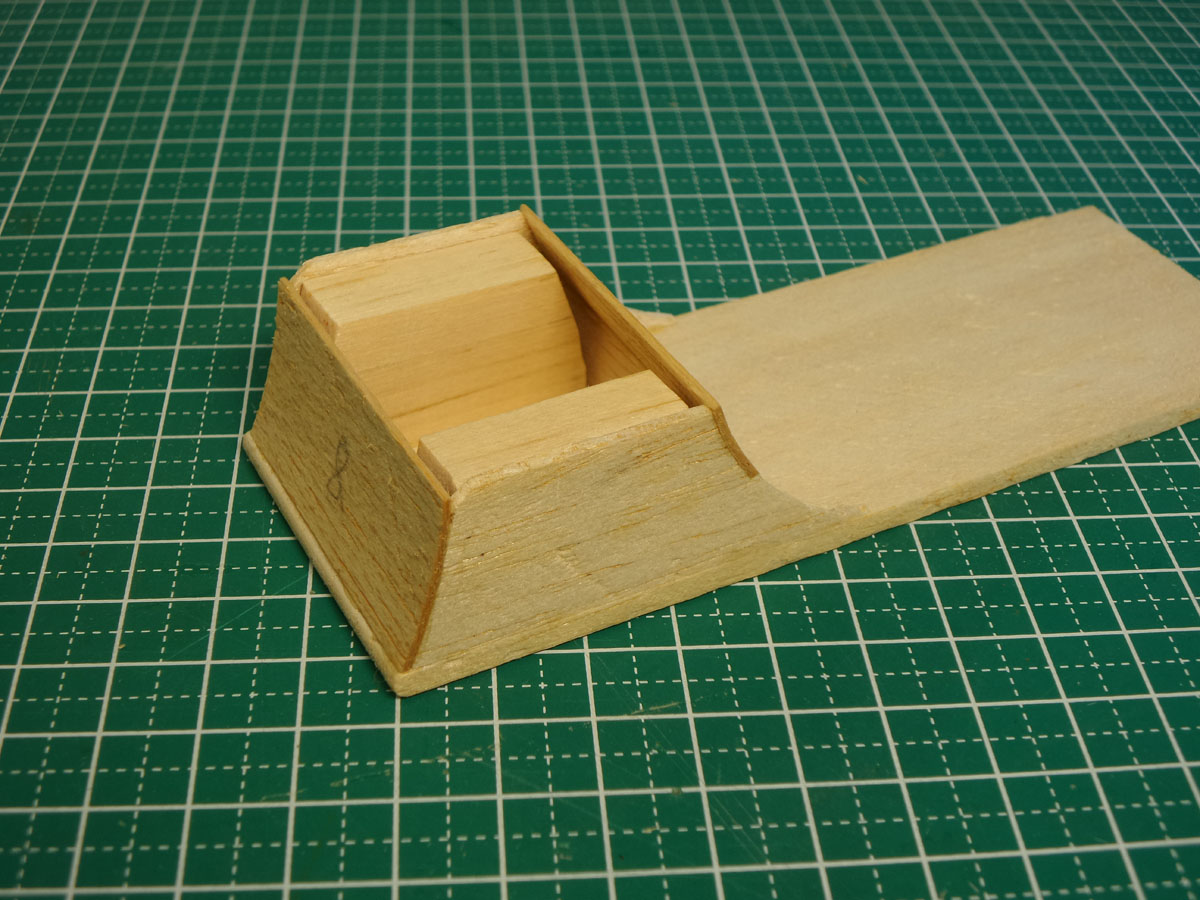

Well, when the detail has dried, it has taken the necessary form. In general, the made matrix is useful still more than once.

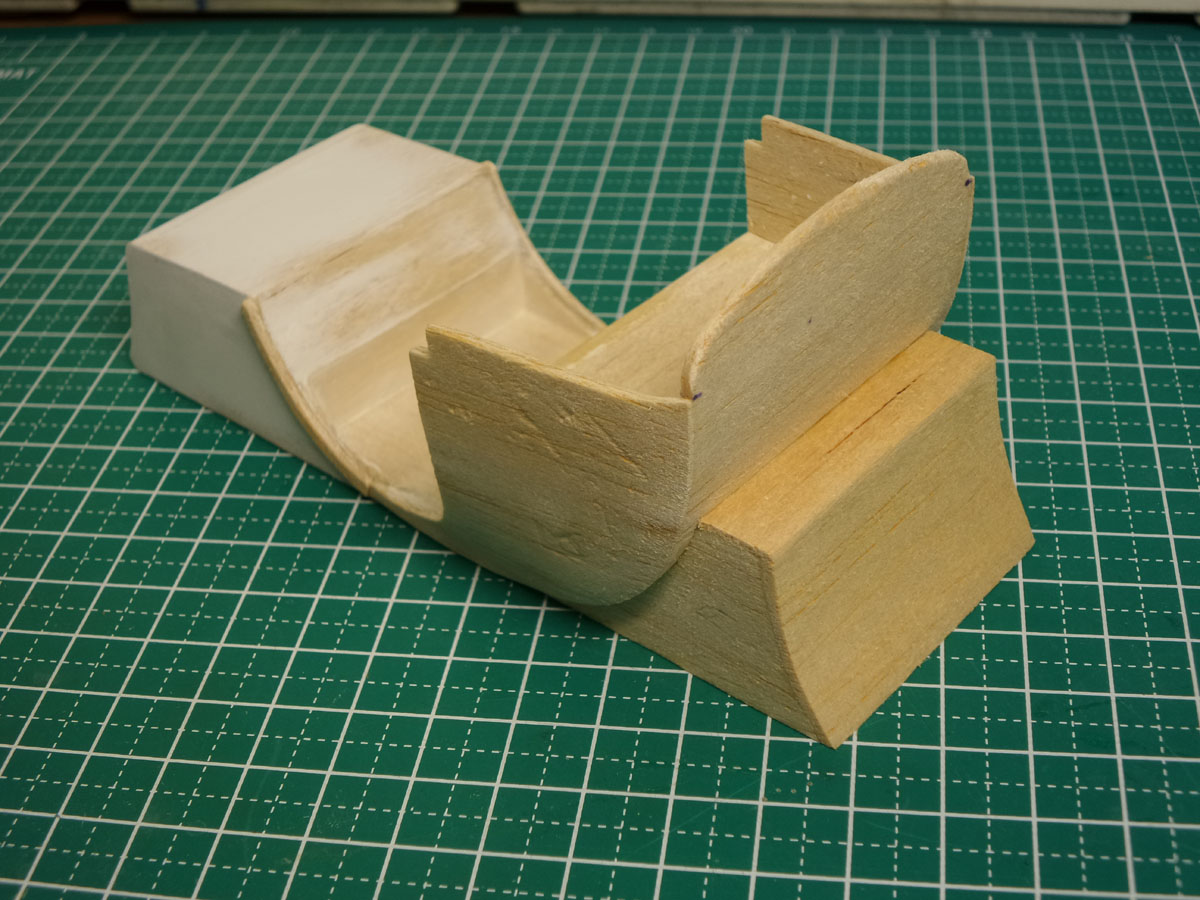

I start sitting assembly further. Quite difficult element because of the rounded shapes. I curved sidewalls on that matrix. At first I have pasted sidewalls, and then a back wall. Though it is more logical former to glue all this at the same time.

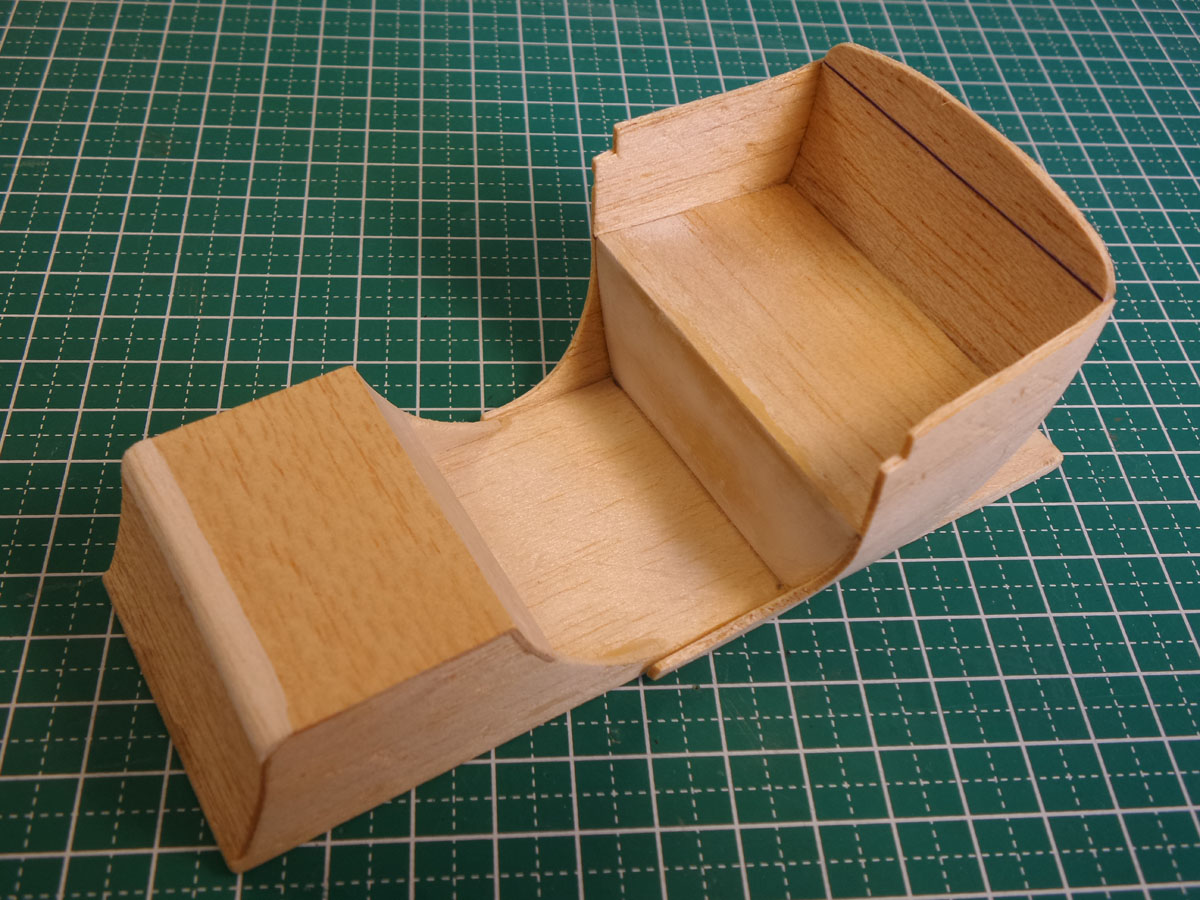

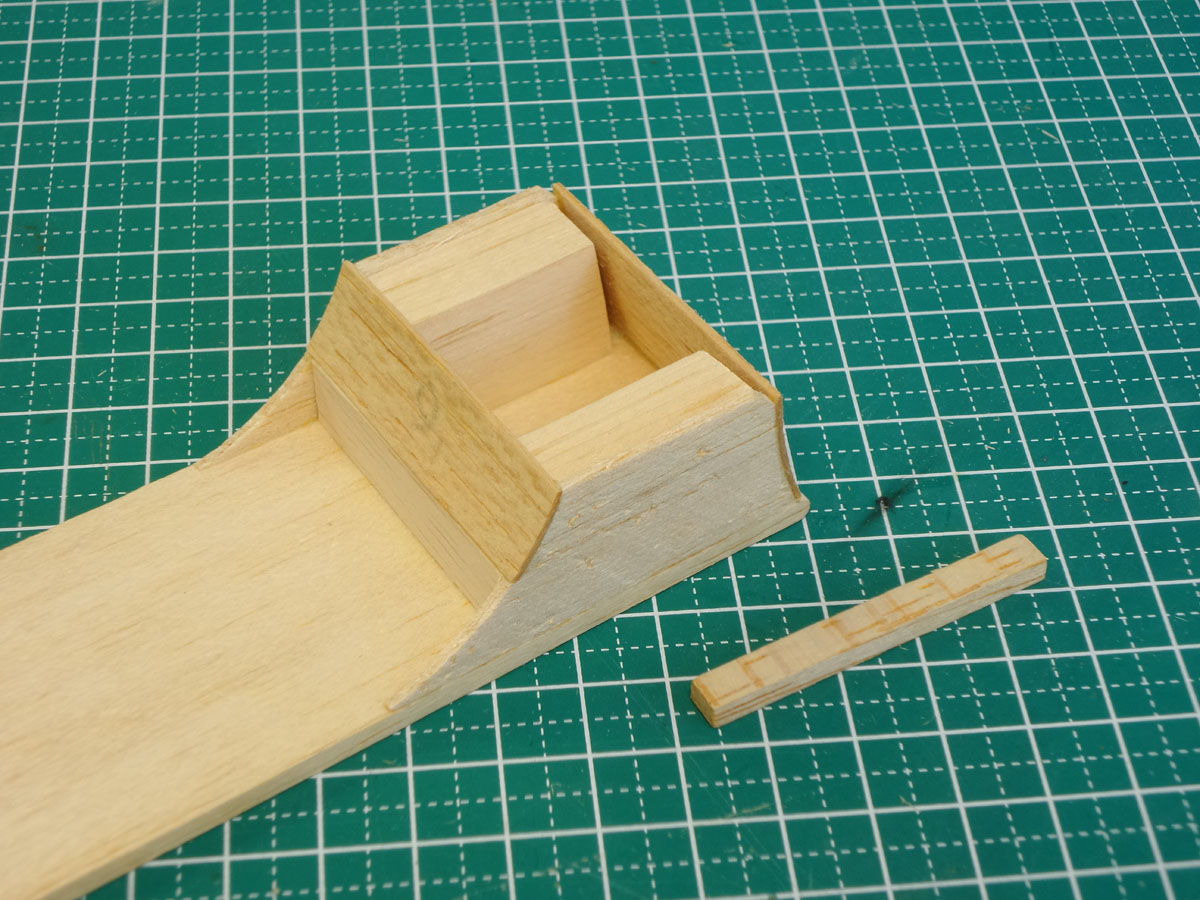

Behind that I have made fitting. it seems looks normally.

I have anew made a side decor of continuation of sidewalls of a seat. So best of all.

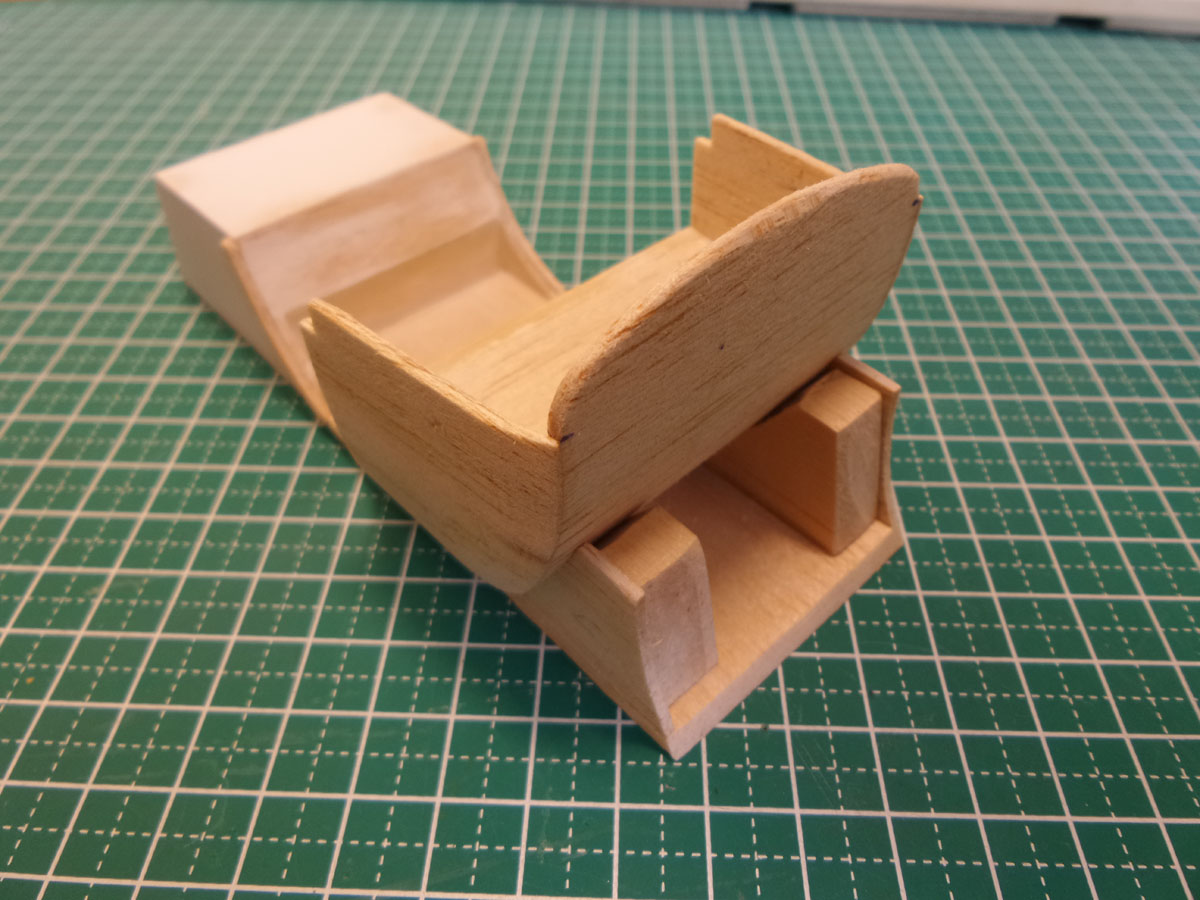

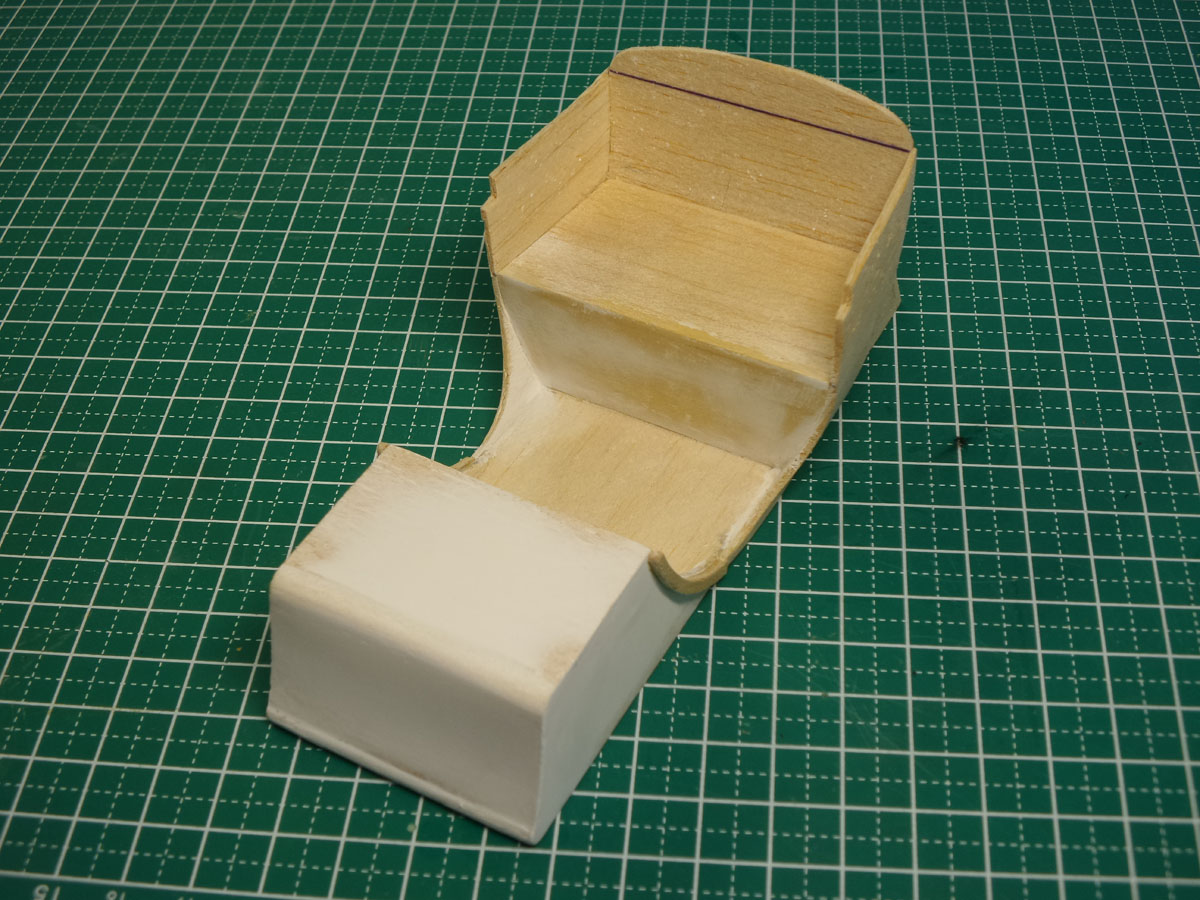

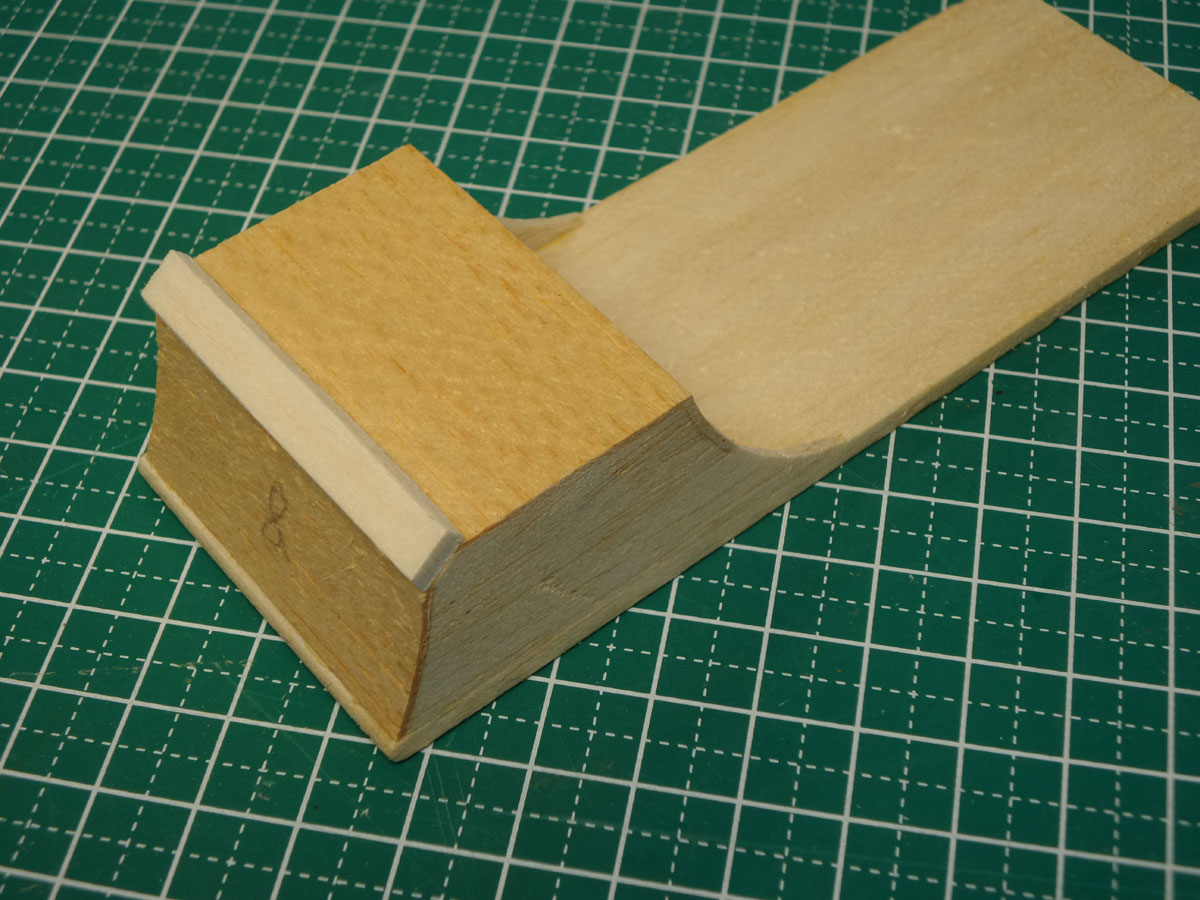

I have pasted a seat to a basis. After that I have covered with hard putty and I have processed a skin a cowl.

And only after that I have pasted a decor. I have begun to collect back part. As well as in a lobby I have inserted lugs for strengthening.

There now and all. The case is finished. Ahead preparation for painting by means of hard putty and a primer.

Part 2

Well, we will start. The plan of model in the section drawings.

We separate the first details of nasal part of a car and we number according to an arrangement on the plan. It is better to make it in advance, and that you will get confused.

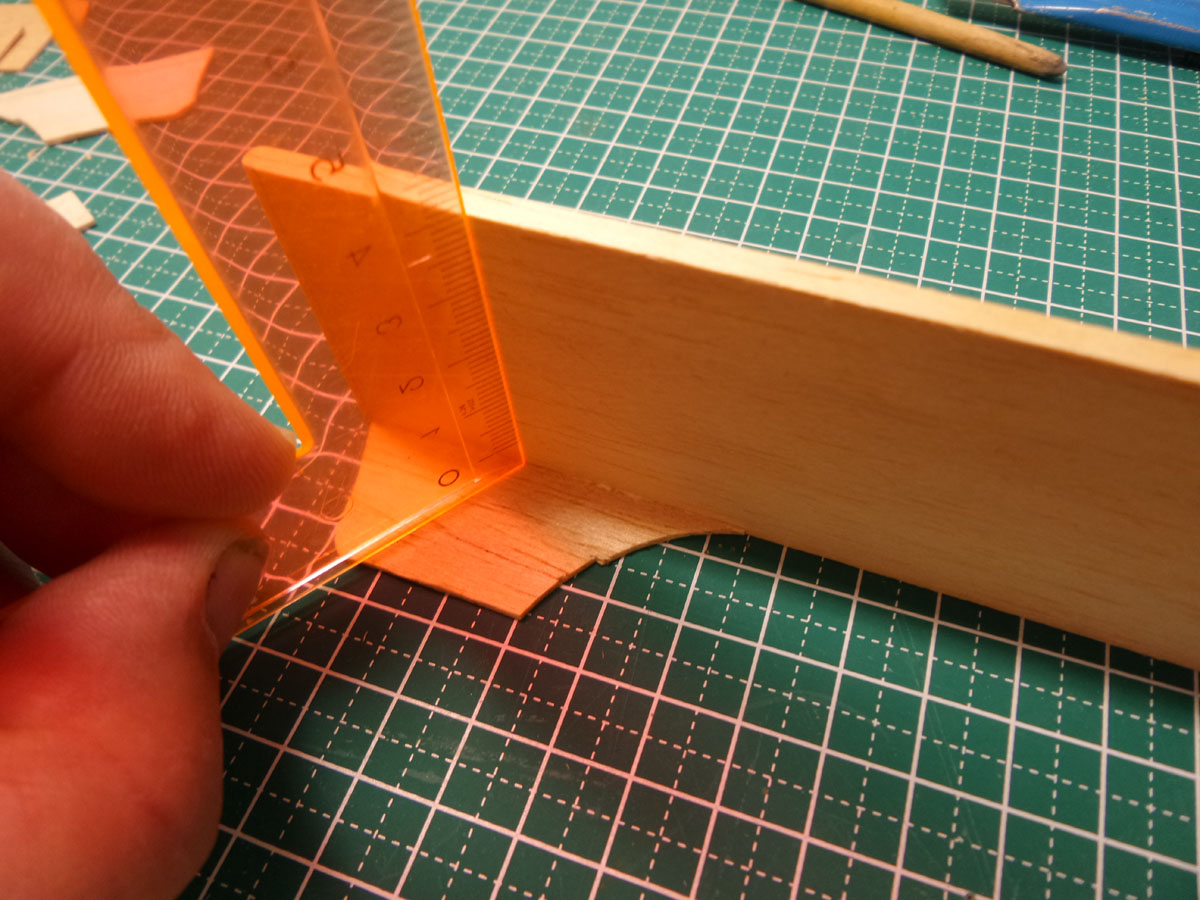

We glue cheeks, trying under 90 degrees. I used a square.

After that I have strengthened a design from within. Also it has been made also because with a bottom will be fastens springs, and sideways lamps. Lugs from a birch.

And further we collect also by glue a nose cowl. I cut out two details from the balsa – the sizes nearly coincided.

While there is an access has puttied a cowl from within. Hard putty on a tree though I like Korean Handycoat more. She is much softer and simpler in processing. I will use her, but not now.

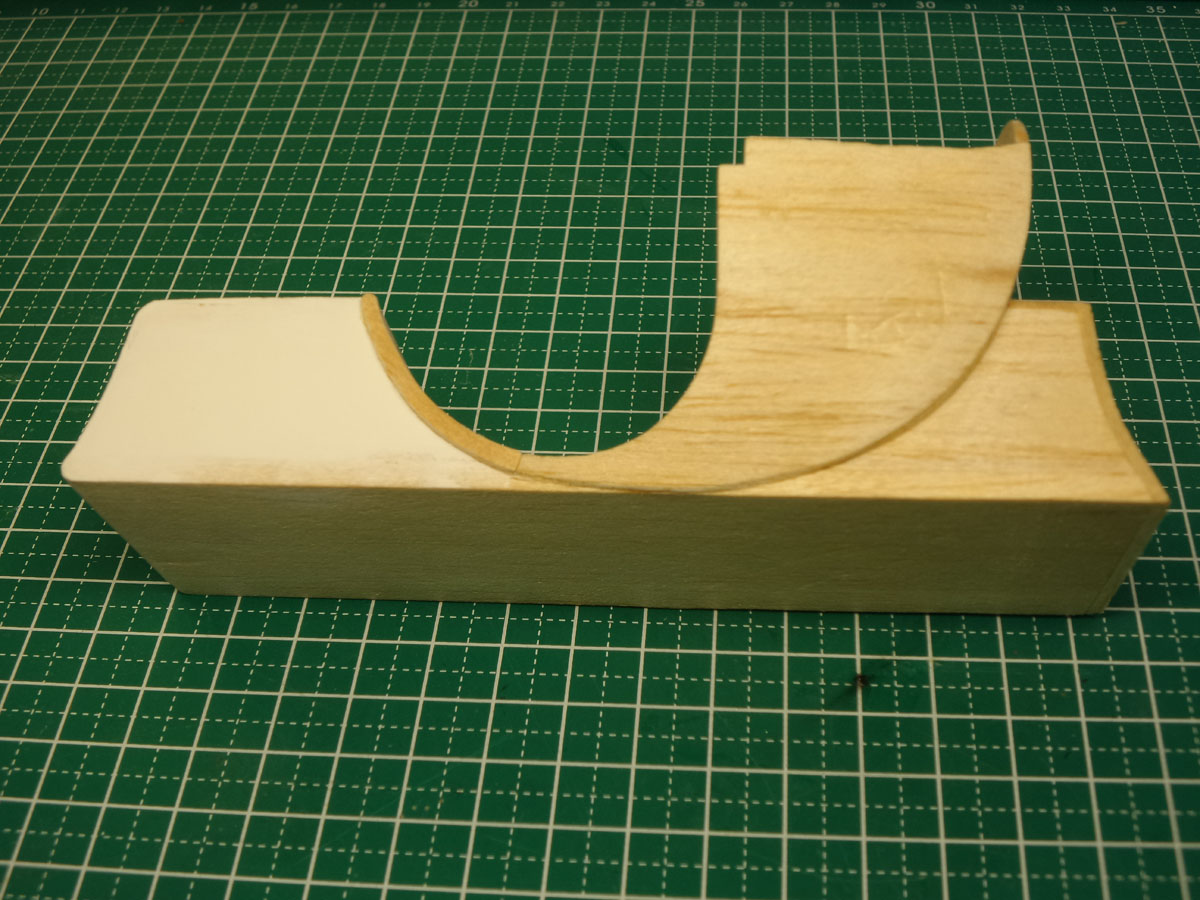

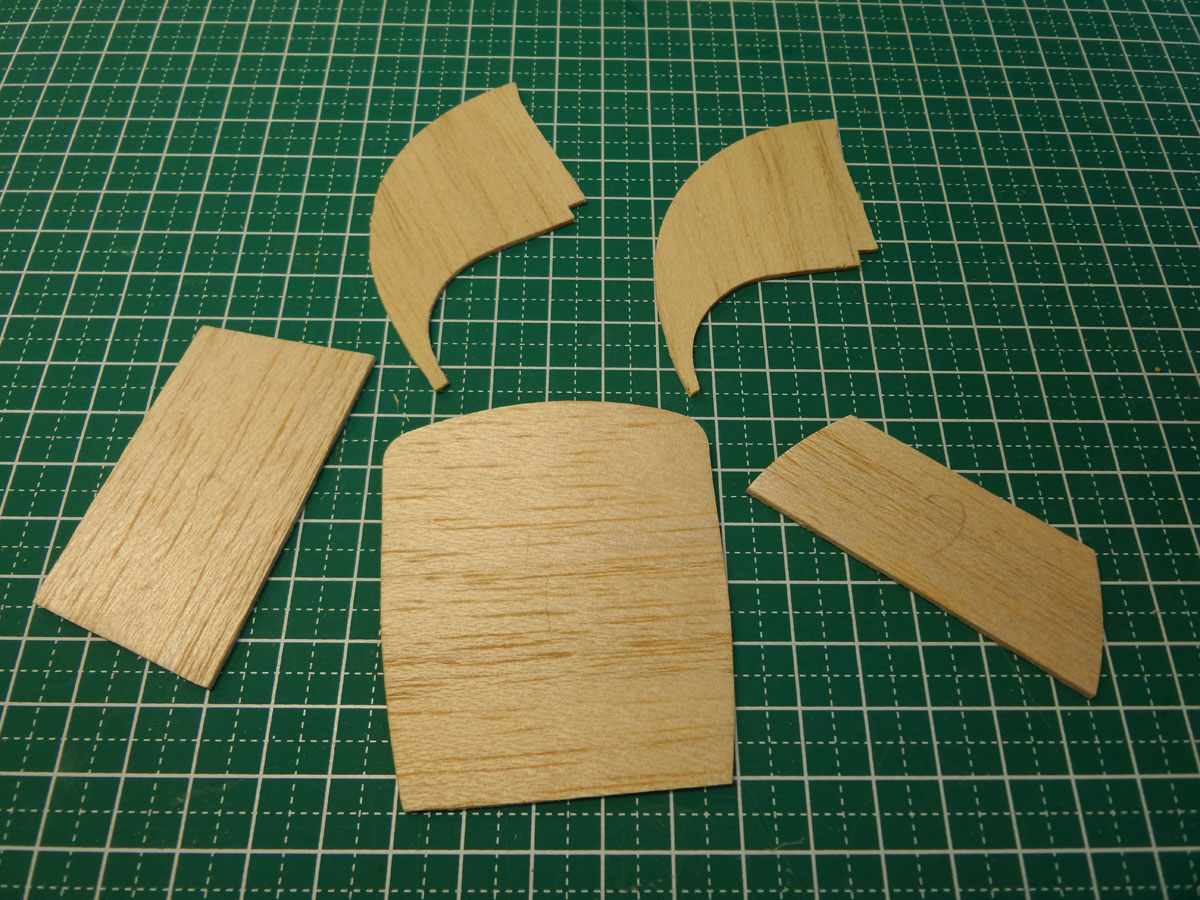

The following step – the case with a seat. It has appeared when fitting likely a detail most difficult here. Difficult because there are a lot of curvatures. Also we number everything.

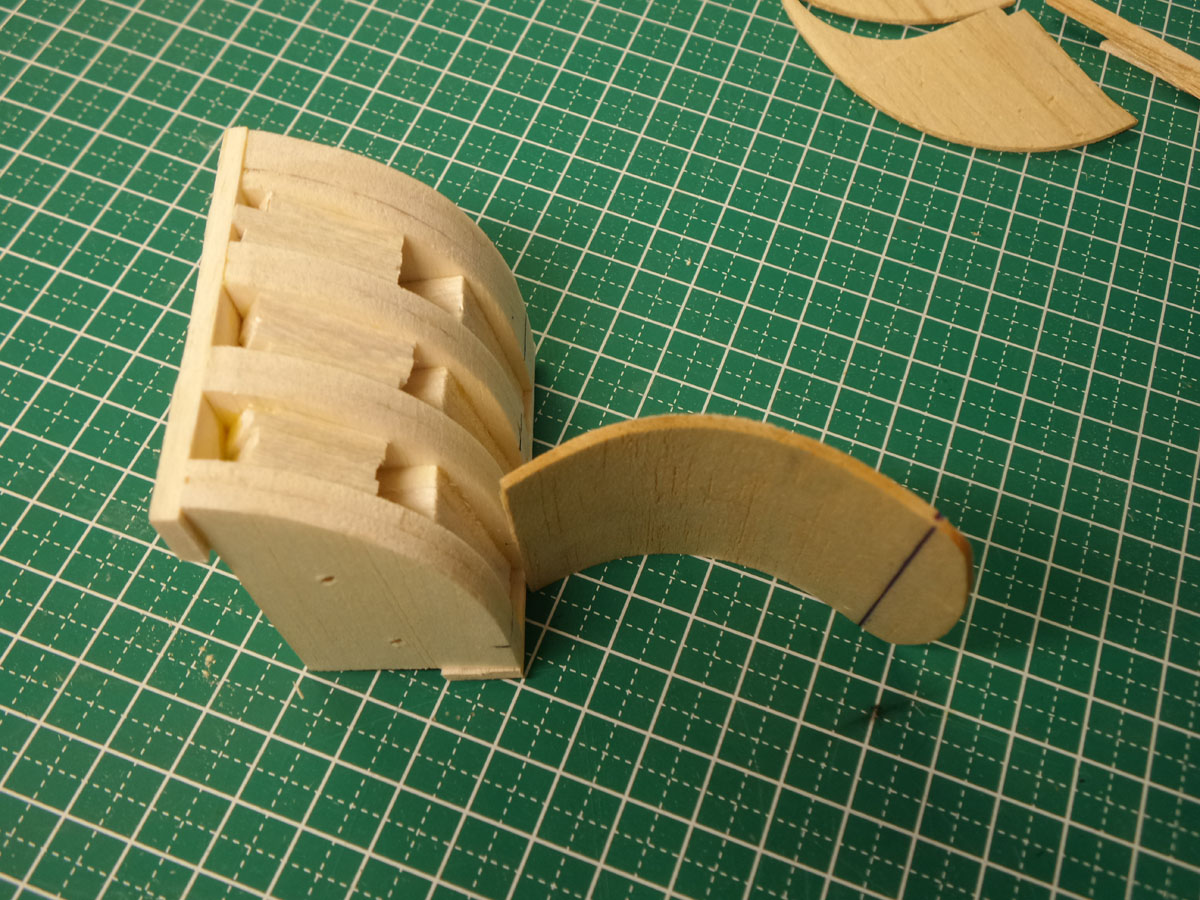

The back wall should be bent. For this purpose I use a template from a framework of details. Also I have stuck together an angular detail of a seat and I have strengthened it balsa laths from within. So, just in case.

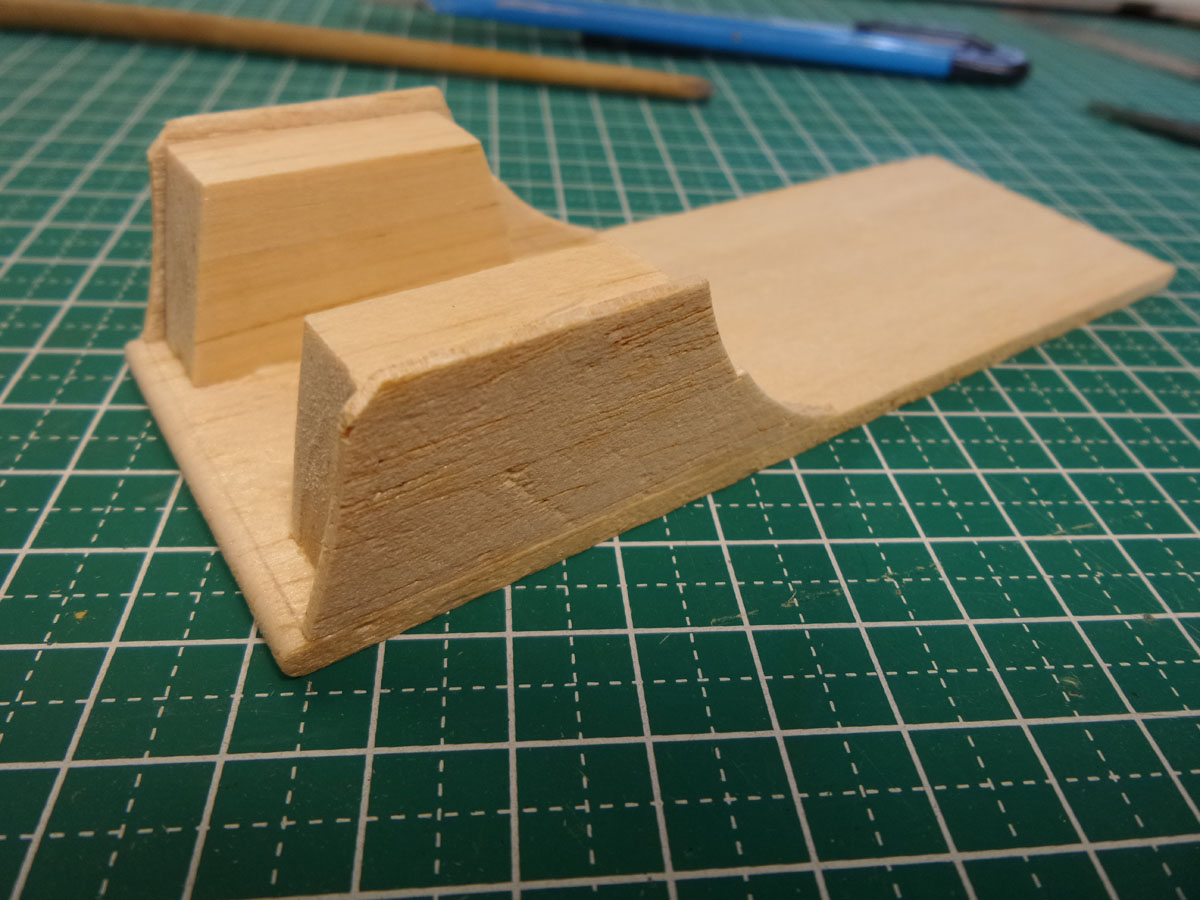

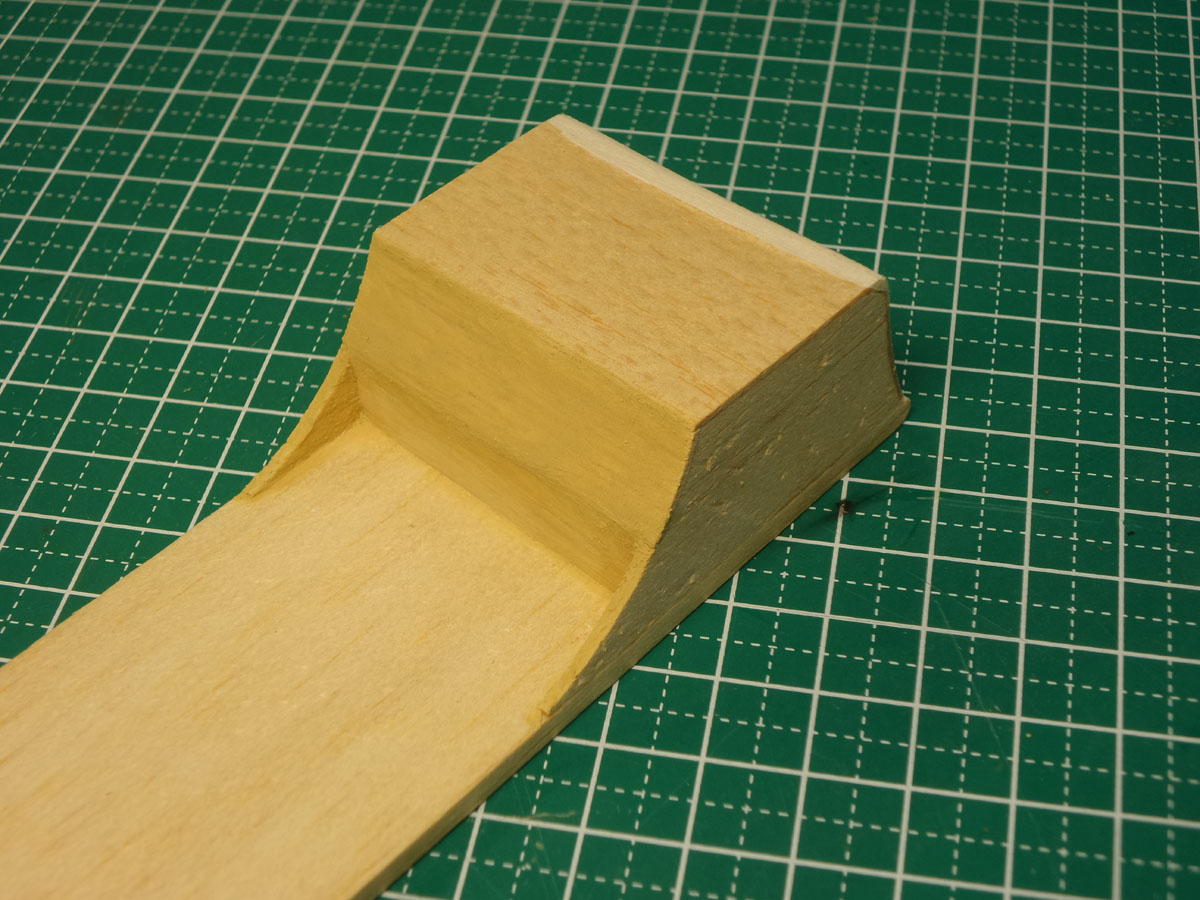

From personal reserves of balsa I cut preparation for a matrix on which I will bend a back wall.

There is such matrix. And further I have filled in preparation with boiled water, I have sustained some time and I have recorded on a matrix. Everything, we will wait.

Photo Packard

The photo gallery of my latest model of Packard of 1900 is added.

I hope to you it will be pleasant.